From crafting the structural frames of cars to assembling intricate components, welding ensures strength, durability, and precision in modern vehicle manufacturing. Its importance extends beyond production, impacting safety standards, design innovation, and cost efficiency.

By harnessing advanced welding techniques and technologies, the automotive sector continues to race forward on the track toward incredible, never-before-seen innovations. This article explores the critical role of welding in the automotive industry, especially for the construction and repair of vehicles.

The Importance of Welding in Automotive Manufacturing

Structural Integrity

Welding ensures the structural integrity of vehicles, as it enables the seamless joining of essential components such as the chassis, body panels, and frame. These connections are essential to a vehicle’s construction, ensuring that it can withstand the day-to-day stresses of driving. Welding directly contributes to the durability of the vehicle, helping it endure pressure, vibrations, and other external forces over time.

Beyond everyday use, welding is critical for crashworthiness. This means that quality welds ensure that vehicles perform well in crash scenarios, dispersing energy and protecting occupants by maintaining the structural framework. Without welding’s precision and strength, the safety of modern vehicles would be significantly compromised.

Cost Efficiency

Welding serves as a pillar for cost efficiency in automotive manufacturing, supporting streamlined production processes that meet the demands of mass vehicle production. By automating various welding processes, manufacturers can reduce assembly times and minimize human error, which ultimately leads to lower labor costs. Automation has revolutionized welding in the industry, allowing for high-quality, consistent welds to be produced rapidly.

Furthermore, welding enables the efficient use of materials by reducing waste. Techniques such as laser welding and robotic systems optimize precision, ensuring only the required amount of material is used for each connection. These advancements have made welding an indispensable component of cost-effective automotive manufacturing, allowing manufacturers to deliver high-quality vehicles to market at competitive prices.

Design Versatility

Automotive manufacturers are increasingly exploring the use of lightweight metals such as aluminum and magnesium, as well as hybrid components with multi-material combinations. Welding joins these disparate materials together, empowering engineers to design vehicles that are lightweight yet strong.

Welding technologies, such as friction stir welding and laser welding, have been instrumental in building EV frames, which require precision and adaptability to accommodate battery storage and other unique design features. This versatility supports advancements in aerodynamics, aesthetics, and performance, ensuring that welding remains at the forefront of automotive innovation.

Automotive Welding Techniques

Resistance Welding

Resistance welding is one of the most common methods in the automotive industry, particularly for joining thin sheets of metal. This technique includes spot welding and seam welding.

Spot welding involves applying pressure and heat through electrodes to a specific point on the metal, creating a secure and durable weld in localized areas. Seam welding, on the other hand, is similar but produces a continuous weld, typically used for long and straight seams.

These methods are highly efficient for assembling body panels and other automobile parts due to their speed and automation capabilities. On production lines, resistance welding streamlines the process while maintaining consistency and reducing production time, making it a staple in mass manufacturing.

MIG (Metal Inert Gas) Welding

MIG welding, known for its versatility and ease of use, involves feeding a wire electrode through a welding gun while shielding the weld pool with inert gas to prevent contamination. MIG welding is suitable for joining metals such as aluminum and steel due to its adaptability.

Its major advantages include simplicity, speed, and the ability to handle a variety of metal thicknesses. MIG welding is commonly used in assembling components like chassis parts, bodywork, and structural frames, where reliability and efficiency are paramount.

TIG (Tungsten Inert Gas) Welding

TIG welding is renowned for its precision and ability to produce high-quality, aesthetically pleasing welds. This method uses a non-consumable tungsten electrode and an inert gas, typically argon, to shield the weld area. It requires more skill than MIG welding but offers unparalleled accuracy.

Due to its precision, TIG welding is ideal for applications involving sensitive or high-standard components, such as exhaust systems, fuel tanks, and decorative features. Its ability to create clean, strong, and visually appealing welds makes it essential for parts where both strength and appearance are critical.

Laser Welding

Laser welding is a cutting-edge technique that uses concentrated laser beams to generate high heat and achieve precise welds. Known for its speed and accuracy, it’s particularly valuable for intricate designs and areas that are difficult to access with traditional welding methods.

This technology is often employed in assembling modern and luxury vehicle frames, where seamless and high-strength welds are essential. Its precision also supports the construction of thinner and lighter materials, contributing to innovation in automotive design and manufacturing.

Friction Stir Welding

Friction stir welding is a relatively newer technique that is revolutionizing the joining of lightweight materials such as aluminum and magnesium alloys. This solid-state process involves a rotating tool that generates heat and pressure to weld materials without melting them, ensuring strong, defect-free joints.

This method is especially significant in the production of electric vehicles (EVs) and fuel-efficient car designs. Its ability to join lightweight materials supports the industry’s efforts to reduce weight while maintaining structural integrity.

Advancements in Welding Technology

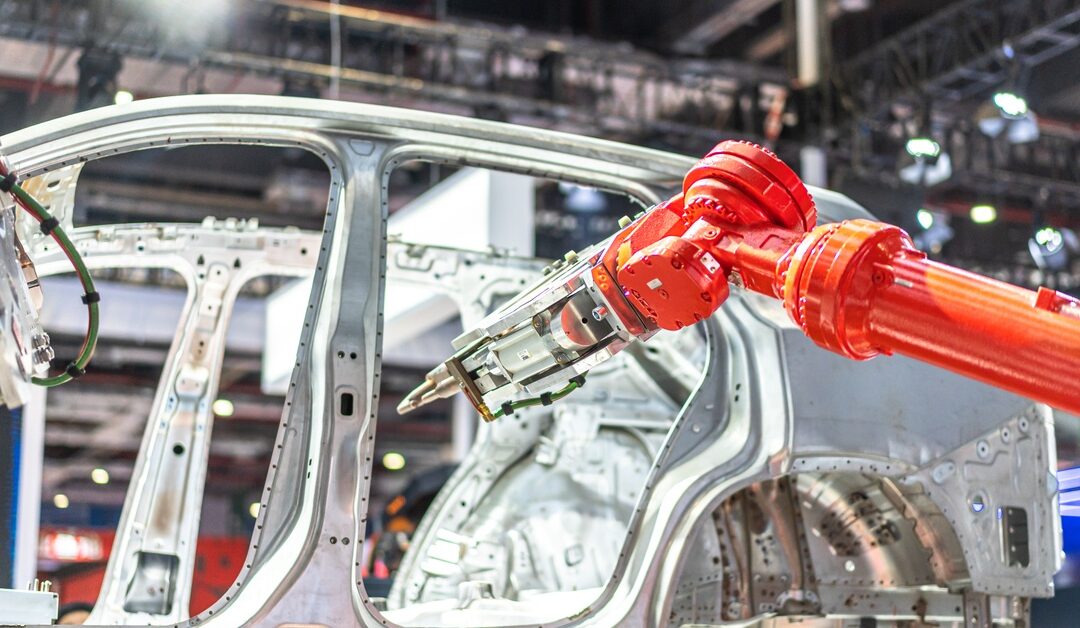

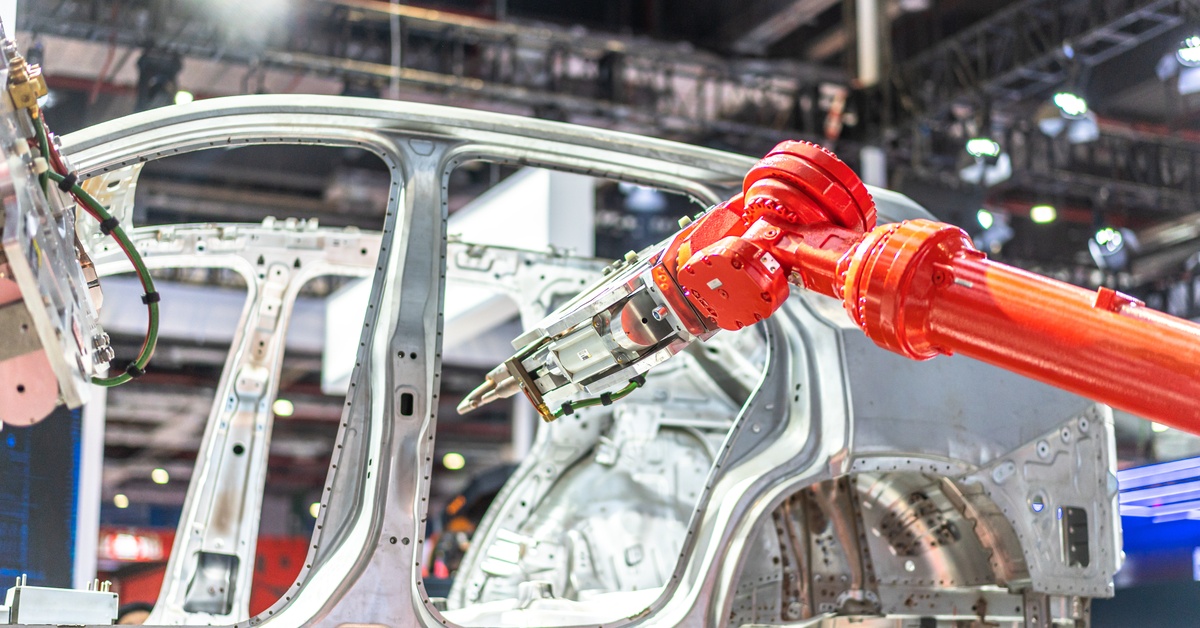

Robotics and Automation

The rise of robotic welding systems is revolutionizing the automotive industry, particularly in assembly plants where precision, speed, and consistency are paramount. Robots with advanced technologies are now capable of performing tasks such as seam welding and laser cutting with exceptional accuracy. Robotic arms, for example, can conduct seam welding in intricate patterns, ensuring minimal errors and perfect joints every time.

Automation has significantly increased production capacity while reducing the likelihood of human error, making it indispensable for high-volume manufacturing such as car bodies and components. By relying on robotics, manufacturers can deliver superior-quality products at a faster rate.

Hybrid Welding Techniques

Hybrid welding techniques combine the best attributes of multiple welding methods to achieve remarkable improvements in joint quality and productivity. One prominent example is laser-MIG welding, which merges the precision of laser welding with the efficiency of MIG welding.

This technique is especially beneficial in creating high-strength yet lightweight joints, a critical factor in producing automotive components such as EV battery casings and lightweight body panels. By integrating hybrid welding approaches, manufacturers can optimize material usage, reduce production time, and meet the stringent demands of modern automotive engineering.

Welding Simulation Software

Advanced welding simulation software is transforming how manufacturers design, plan, and optimize welding processes. These tools allow engineers to visualize and test joint designs in a virtual environment, identifying potential issues long before production begins.

By reducing the need for physical prototypes and extensive testing, welding simulation software saves time and costs while improving workflow efficiencies. It also enhances the precision of fixture design and material compatibility, ensuring smooth execution during production. For the automotive sector, these simulation technologies have become invaluable for streamlining complex welding processes.

The role of welding in the automotive industry is undeniably vital. It’s the foundation upon which the strength, safety, and innovation of vehicles are built.

At Muggy Weld, we’re proud to support professionals and enthusiasts alike by providing high-quality welding supplies and educational resources through our online welding shop. Whether you are starting your welding journey or are a seasoned expert, we are here to empower you with the tools and knowledge you need to succeed.