I didn't forget you, but had to put the project aside for a while. I'm still not done as I wanted to include a pic of the fitting installed in the cowling but I can send that latter.

I think the original question was -- is there an issue with welding a steel cad plated bolt to Al? From the pics I think the answer is clearly no. Although the it appears that there is no cad plate left on the working end

of the clevis. But that won't be a problem.

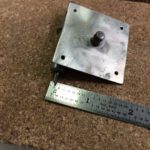

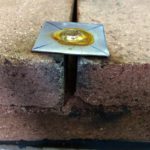

The problem in this weld is that the 1/4 inch Steel clevis pin and .030 Al sheet have drastically different Temp coefficients and mass so getting an even temperature was difficult. After a couple of not so pretty attempts, I

put the clevis between the fire bricks as shown and carefully heated from the bottom. The result isn't perfect but good enough. I'll place a backing plate over it as shown, and then rivet the assembly to the cowl. The extra

plate probably isn't necessary.

After I finished a friend suggested a better way. Buy a used toaster oven which can easily cook to over 350 degrees, heat the assembly in the oven and then apply the weld rod. That should provide an even temperature across both parts. I haven't tried it but if I have another application I'll give it a try. BTW a friend who is an AI (licensed Aircraft Inspection Authority) was impressed, but technically it's probably not legal. And it is quite

strong.

I just wanted to tell you about a repair that I made that I probably never would have even attempted without your SSF-6 Silver Solder. I have attached some before and after photos.

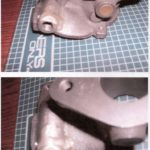

My customer sent me a cast iron body carburetor to repair that had a piece broken out of the casting at the threaded hole where the inlet fitting screws into. It was a 1/8 NPT fitting, and someone had just tightened it too much and broke the casting. The broken piece was long gone. Someone had previously tried fixing it with epoxy, but it had ultimately failed. When I first saw it, I wasnt sure it was even possible to repair it without the broken piece, being such a small casting. I was afraid the heat from welding or brazing would warp it. Then I remembered I had some of your SSF-6 silver solder left over from a manifold repair I had done earlier in the year.

I figured I had nothing to lose, so I cleaned and prepped the casting, cut the threads off a 3/8 x 2-1/2 hex bolt and threaded the shank with a 1/8 NPT die. I coated the threads of the bolt with graphite to keep the silver solder from sticking to it, then screwed the bolt into what was left of the hole until it was fully engaged into the threads in what was left of the casting.

I clamped the casting into a large vise to act as a heat sink, and using a #3 torch tip, built up the area with SSF-6. After cooling for about 2 minutes, I carefully unscrewed the bolt. It had left almost a perfect set of threads in the SSF-6.

After it was completely cool, I bead blasted the casting and ran a 1/8 NPT tap through the threads just to clean them up. I assembled the carburetor and leak tested it, and there were absolutely no leaks!

My customer is very happy. Since neither the casting nor the complete carburetor are available any longer, my only other alternative would have been to search for a used one for her. Thank you very much, from both me and my customer, for a great product!

Thank You MuggyWeld!

Seriously, i just received my Super Alloy #1 and used it! I found this product during a YouTube search and could not believe a product was this fast and easy to use. A local hardware store told me they had some aluminum brazing rod that would work on the project i was working on, boy where they wrong! Frustrated, I decided to order your product and to say the least i am impressed! This by far is the best product i have ever used, and i will continue to buy more!!!! I will post pics and project when they are done!

Excellent product, service and support.

Thanks a million!

Your SSF-6 product is great stuff. I've used it to fabricate and repair a number of tools and fixtures for our sewing business. I see you guys are in Olympia--glad to support a local company doing good work.

My Super Alloy 1 starter kit was delivered few days ago. I tried it in the damaged carburetor and it worked perfectly. I’ve been able to patch a crack and a hole and tap a new thread. Now it’s back to life!

This product is a lifeline for the vintage auto enthusiast.

I’m very satisfied! Thank you for your support.

Best regards,

Ernesto

P.S. I wrote a positive review on amazon.

Another success story: two Mercruiser exhaust manifolds cracked over the winter due to the oversight (mine) of draining a couple of hoses. The manifolds were welded and reinstalled. At the lake yesterday, no leaks. Good product!

2nd Email:

Mike,

Thanks for the message. When I started up my boat before Easter, my heart sank when I saw water pouring out both exhaust manifolds (V-6, mercruiser). Fortunately, I have a neighbor who is truly a man of great knowledge and mechanical skill. I asked him about my situation. He initially recommended brazing, but learned of Muggy Weld through YouTube. I ordered 1/2# of #72 and 1/2 # of 77, but my neighbor only used the 77 rods - all seven on the repair. Both manifolds came out looking great and passed the water test last week with no leaks. I thought about taking photos of the cracks before the repair, but I felt so stupid since it was all my own fault that I didn't. I'll send you a photo of the manifolds installed that shows them looking great. The cracks were pretty bad. A replacement Mercruiser exhaust manifold is about $300. and both were cracked.

In peace, Mark Lawlor, Charlotte, NC

From the neighbor, David Fortenbery:

Mike and Mark,

I hope you don't mind Mark, (I guess I am giving away your secrets!) but I thought it might be helpful to Mike to outline the procedure used to fix the manifolds.

Mike, I am Mark's neighbor and helper. Here tis...

Opened the crack from end to end with grinder, flap wheel, Dremel...

Stop drilled end of each crack "leg" with .1875 bit.

As the cracks were in the water jacket only, we decided to use 7700 rod for machinability.

The manifolds were pre-heated to 450 degrees in oven for 2 hours.

We used a PowerCon 350 DC welder at about 70 amps, and welded 1 inch at a time. Immediately after the 1 inch of weld, we "shot peened" with air hammer and pointed chisel. This removed the slag and left the surface of the new weld dimpled. (golf ball-ish!)

This was repeated over and over until parts of the weld were "proud" to the rest of the manifold. The high spots were removed with flap wheel. This made the low areas very visible. We kept a Dremel with grinding disk handy and if we saw any little cracks, we ground them out and re-welded. Each weld was followed by peening.

As soon as the welded area was flush, we peened entire welded area and let the peening overlap the cast iron about .75 to 1 inch. This was to stress relieve, but had the added effect of giving the weld the appearance of a sand casting! Serendipity.

Then immediately back in oven at 450.

Repeated for second manifold. (When old Mark busts a manifold, he busts 'em both!)

After both were in oven, we decreased oven thermostat about 50 -100 degrees per hour and NEVER opened oven. After "cooking" overnight, they were done.

We worked out this procedure after studying your website and watching numerous videos on welding cast iron. This hyper young man (Chuck) has a whole series of videos that were very helpful to us... If you have not seen his videos, check him out and for heaven sakes, send him some Muggy rod!

https://www.youtube.com/watch?v=Yopcz-IYDyQ (this video is not specific to what we did, I listed it so you could find young Chucky)

Hollar if we can be of any assistance...

Dirty Dave

Got my Super Alloy 1 kit on Saturday and used it to repair a pewter tankard with a broken hinge on the lid.

In 40+ years as a jewelry repairman, pewter repair has always been considered "impossible" but the repair was fairly easy with the Super Alloy 1.

Heat control was very important as the tankard lid was very thin, but in the end the repair was strong & serviceable.

A quick touch-up with artist paint matched the old oxidized color of the lid & the customer was very happy.

Thanks for an excellent product & the online videos were very informative and helpful.

I would have bet this was a waste of money. Boy, was I wrong! The fan on my antique car hit the radiator when the one lower mount bolt fell out. It just hit 10 of the tubes slightly. Your Super alloy 1 fixed the tubes without much difficulty. It did take a little learning experience, but I couldn't be happier. It saved me a $450.00 custom made aluminum radiator.

Here are the pictures that you requested.

The copper pieces are 2" plumbing end caps that had been cut back.

We used MuggyWeld SSF-6 to solder 18-8 Stainless Steel Socket Head Cap Screws to 23 copper end caps.

On an additional 23 end caps we used MuggyWeld SSF-6 to solder both an 18-8 Stainless Steel Socket Head Cap Screw and a 304 Smooth-Bore Seamless Stainless Steel Tube in one operation.

You can see in the last photo that the SSF-6 traveled through the hole in the copper, wetting the SS screw threads.

I selected Muggyweld for this operation because it wets stainless very easily, and its melting point seems to be about 100 F lower than the standard high silver content silver solder.

We have not performed any evaluation of the strength since it is already clear to us that it is sufficient for our needs.

We will observe the joints over time to determine any aging effects that could adversely affect our application.

You have an amazing product.

After numerous failed attempts to repair my pot metal grill, not to mention the further damage I caused, you solved my problem with Muggy Weld. I made a copper plate copy of the missing piece which lapped behind the grill about 1/2 in. I sanded front and back of both pieces, clamped them together, and soldered from the front side only. I concentrated the heat mostly on the copper. The Super Alloy 1 traveled all the way thru the lap joint to the back. After cooling I was able to build up the copper with Super Alloy 1 until it was flush with the pot metal. The piece sanded to a ready to chrome finish.

1951 Packards aren't worth much but I've had fun restoring it and my grandkids think it's the coolest car ever. My wife says it's the ugliest car she's ever seen and no wonder they went broke.

Thank you for your great product and your excellent instructional videos.