How to Repair a Cracked Engine Block

As you can imagine, a frozen or cracked engine block is an issue of serious concern.

While many car owners might believe the best course of action is to sell the vehicle, it does not have to come to that, provided you address the issue immediately.

Ignoring a frozen or cracked engine block only leads to more significant problems. If you have the right tools at your disposal, you can have yourself back on the road in no time.

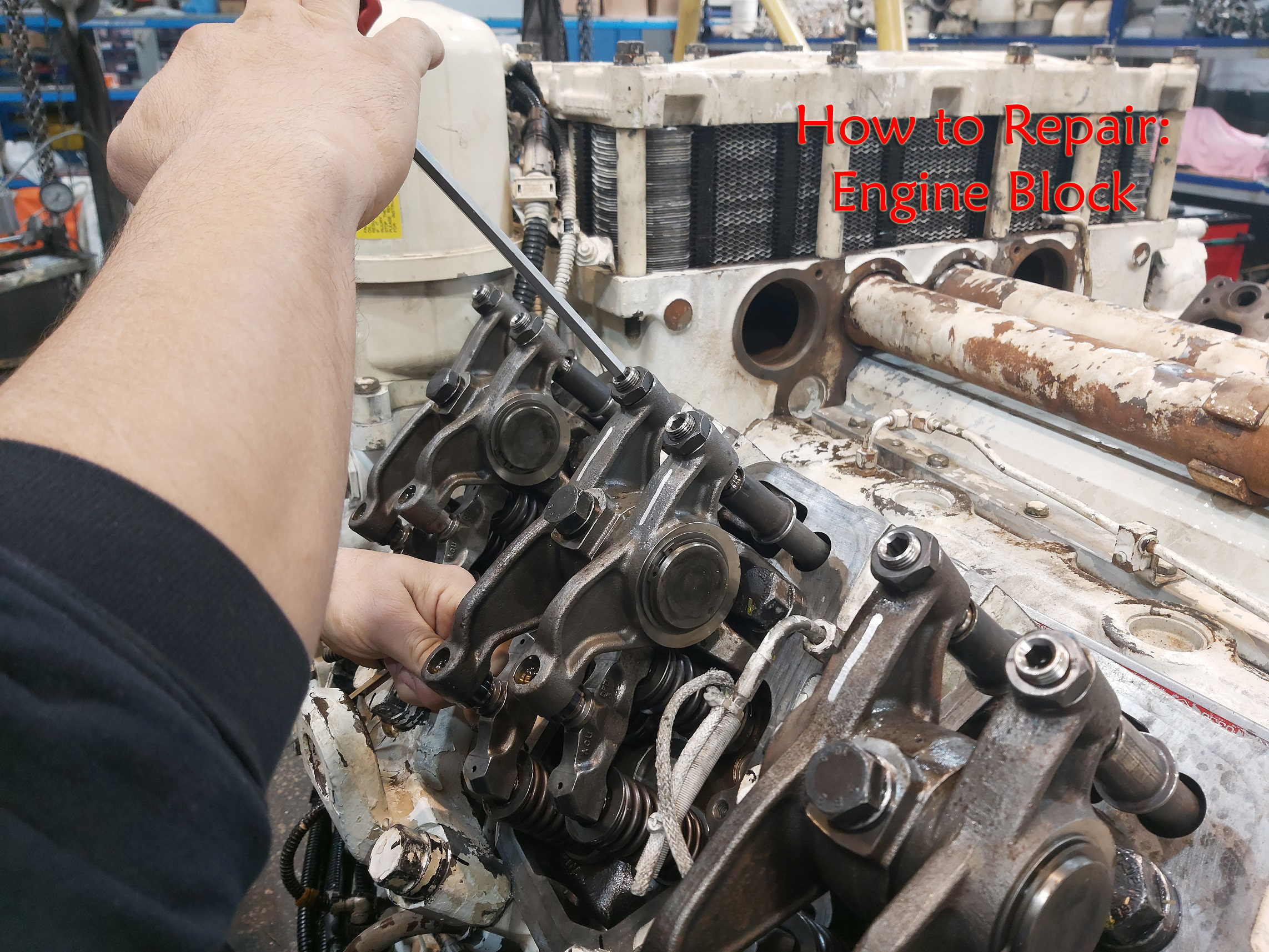

Assess the Damage

Before you begin, you need to understand how bad the damage is.

Start by investigating high-stress areas. For example, the cylinder heads, spark plugs, valve seats, and other places around the combustion chamber.

Alternatively, perform a magnetic particle test. This method identifies flaws in the engine block and can indicate how deep the crack is, which you might not be able to assess on your own.

It’s also a good idea to search for the source of the crack. Otherwise, you may need to perform this step again in the future.

Repairing a Cast Iron Cracked Engine Block

Most older engine blocks are made from cast iron. While it’s durable, it can also be brittle and porous. As such, it requires a lot of patience and care when welding a cast iron cracked engine block.

Start by cleaning the area as best as you can. It’s a good idea to soak the engine block in boiling water. This will remove any stubborn oil stains.

Dependent on which cast iron welding rod you’re utilizing to repair the motor block, you may need to pre-heat your part to at least 500 degrees Fahrenheit. Just don’t go beyond 1200 degrees, or you may cause further damage to the engine block.

You also want to keep the temperature even across the engine block. If an area suddenly loses heat, you might cause additional cracks or worsen existing damage. When welding a cast iron engine block, it’s important to remember that it will retain heat and not transfer the temperature quickly.

Move the weld inch by inch using short passes and clean the engine block in between. Alternatively, you can peen the welded area allowing the heat to gravitate toward the open pores.

Once you’ve completed the repair, slowly bring the entire engine block down to an average room temperature. This might take some extra time. However, it will guarantee a tight weld and ensure that your engine block won’t crack under strain.

Ensure You Have the Right Equipment

Sure, there are other methods to repair a frozen or cracked engine block. But compared to these alternative techniques, welding produces a stronger bond as existing materials meld with new metal. It also allows you to get deeper into a crack to ensure you won’t have to go through this process again.

However, to achieve a successful repair, you need the right equipment. Our Cast Iron Repair Kit for Arc Welding saves you from pulling apart machines and placing the part in the oven before commencing work. No pre-heat or disassembly is required with this cast iron welding rod. If you can reach the crack, you can repair the motor block without taking the engine apart. Simply identify the area and repair it with this tool. Get your hands on the Cast Iron Repair Kit for Arc Welding and save time, money, and energy today!