How to Solder Two Pieces of Broken Pot Metal at 350º F

In this video, you’ll learn how to repair a broken pot metal table leg using Super Alloy 1 multi-metal solder and a propane torch.

This pot metal table had been passed down for generations, becoming a family heirloom. The Muggy Weld customer requesting the repair was quite upset when her husband fell on the table, breaking the pot metal leg.

We pre-cleaned the broken table leg prior to applying the flux or solder, to ensure proper bonding. A Dremel tool, sandpaper, wire brush etc can be used for this task.

Next, we preheated the broken pot metal. The broken leg was very heavy so we heated the pot metal part considerably longer than you would if it was smaller or thinner.

We applied the flux all around the gap in the broken pot metal and continued to broadly heat the pot metal, being careful not to focus the torch on any one area.

Once the broken pot metal reached the proper working temperature, the flux changed color from honey to root beer, indicating it was time to apply the solder.

Because the pot metal part was broken in two, we needed to flip the leg over and solder the other side of the pot metal.

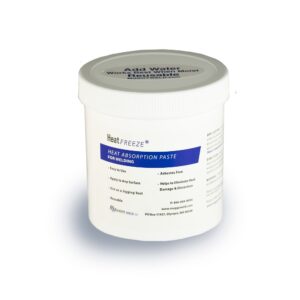

When heating the opposite side we were in danger of loosening the solder already in place. To remedy this situation, we packed the area with Heat Freeze Heat Paste to stop the heat transfer. This unique product saved us time and headaches as we would have been playing the game of soldering one side and then the other.

TIPS:

- Always use adequate Heat Freeze Heat Paste to ensure your part is fully protected

- Always allow your part to cool completely before removing the Heat Freeze Heat Paste for your safety and the safety of your part

- Keep Heat Freeze Heat Paste clean to ensure long life of the product

- For best results, occasionally add water to Heat Freeze Heat Paste as necessary to keep moist

- Allow adequate space between Heat Freeze Heat Paste and the area to be welded. Heat Freeze Heat Paste works so well it can absorb the heat from the area needing to be repaired

- Wash hands after handling Heat Freeze Heat Paste or use gloves to apply

Note: Please observe all AWS Safety & Health Guidelines when using Muggy Weld products.