Solder Pot Metal or Zinc Die Cast Cracks at 350°F with Muggy Weld Super Alloy 1 Multi-Metal Solder.

Cracks or gouges in zinc die cast/pot metal is the #2 pot metal restoration problem, second only to pot metal pitting. For this instructional video, we simulate cracks in pot metal by using a Dremel tool to create a groove in a pot metal part.

The first step for any pot metal cracks repair is cleaning the pot metal. We recommend using a Dremel as shown to prepare the cracks before beginning torch work. Note the technique: it’s vitally important to remove all oxidation or impurities from the pot metal cracks prior to soldering. Be sure to strip all pot metal surfaces before you begin to solder the pot metal cracks.

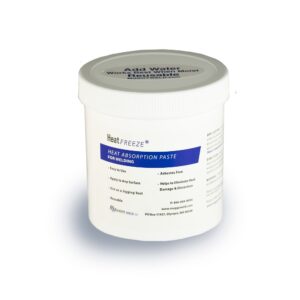

We were demonstrating this pot metal cracks repair using a pot metal piece previously featured in our “pot metal pits” repair video. We were aware that the previous solder could loosen if we didn’t stop the heat from spreading, so we used Heat Freeze Heat Paste to stop heat transfer and to protect an existing solder repair in the adjacent area.

For your safety and the safety of your pot metal part, allow pot metal to cool completely before removing Heat Freeze. After use, simply return Heat Freeze Heat Paste to its jar and reuse indefinitely.

Excess flux can be removed with warm water and a wire brush. Super Alloy 1 is a perfect match for pot metal, so no one will ever notice the cracks you’ve repaired with Super Alloy 1 pot metal solder and flux kit.

TIPS:

- Use adequate Heat Freeze to ensure previous solder has been completely covered

- Always allow pot metal parts to cool completely before removing Heat Freeze

- If Heat Freeze dries out, add water as necessary to keep moist

- Apply Heat Freeze with gloves and wash hands after use

Note: Please observe all AWS Safety & Health Guidelines when using Muggy Weld products.