Pot Metal Restoration tips with Super Alloy 1 and Heat Freeze Heat Paste

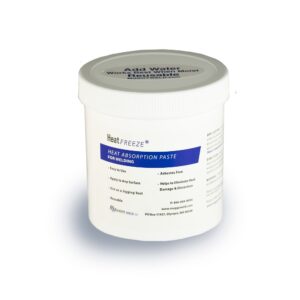

Muggy Weld customer Greg sent these photos and a testimonial of his 1929 Nash Touring Car restoration project. The windshield rail was broken in 3 places, so Greg purchased Super Alloy 1 rod and flux to repair the typically impossible pot metal alloy. After soldering the front side of the pot metal part with Super Alloy 1, he then used Heat Freeze Heat Paste on the back of the part to prevent a remelt–which is common when a previously soldered area is reheated on the backside.

Dear Muggy Weld:

Here are those pics of the windshield repair of the 1929 Nash Touring Car. The Super Alloy 1 low temp solder and Heat Freeze did the job.

The products and instructional videos are great, because they do actually work as advertised. Not only was it a strong repair, but I was able to drill and tap threads into the material for mounting. Here is the finished product.

Next time I have some kind of tricky metal to repair, I’ll be sure to give you guys a call.

Greg

As you can see, classic car/irreplaceable parts can be easily repaired with Super Alloy 1 rod and flux and a propane torch.

TIPS:

- Always use adequate Heat Freeze Heat Paste to ensure your part is fully protected.

- Always allow your part to cool completely before removing the Heat Freeze Heat Paste for your safety and the safety of your part.

- Keep Heat Freeze Heat Paste clean to ensure long life of the product

- For best results, occasionally add water to Heat Freeze Heat Paste as necessary to keep moist.

- Allow adequate space between Heat Freeze Heat Paste and the area to be welded. Heat Freeze Heat Paste works so well it can absorb the heat from the area needing to be repaired.

- Wash hands after handling Heat Freeze Heat Paste or use gloves to apply.

Note: Please observe all AWS Safety & Health Guidelines when using Muggy Weld products.